Concurrent Precipitation and Grain Growth Simulation

Reference Folder: $Pandat_Installation_Folder\Pandat 2024 Examples\PanEvolution\Grain_Precipitation\Ni-14Al_Microstructure_Zener.kdb

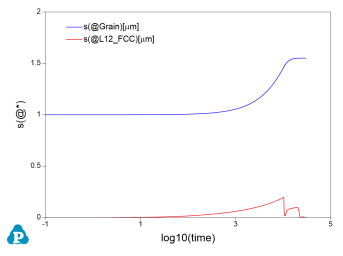

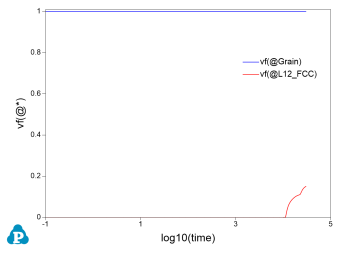

This example is to demonstrate how to perform a simulation of concurrent precipitation and grain growth. In this example, the alloy composition is Ni-14Al at.%, which is first isothermally annealed at 800 °C for 10000 seconds and then continuously cooled to 550 °C from 10000 to 30000 seconds. The alloy composition and heat treatment condition are given in “Ni-14Al_Microstructure.pbfx”. In the first simulation, the Zener pinning effect is not considered by default. Initially, there is no L12_Fcc (γ’) phase and average grain size is 1.0µm in lognormal distribution. The initial microstructure is set in Al-Ni.ini as shown below

<Grain name="Fcc">

<Parameter name="size" value="1e-6" description="average size" />

<Parameter name="volume_fraction" value="1" description="volume fraction" />

<Parameter name="size_distribution" value="2" number_cells="1000" sigma="0.3" description="initial psd shape: 0-uniform; 1-normal; 2-lognormal;10: user-defined psd" />

</Grain>

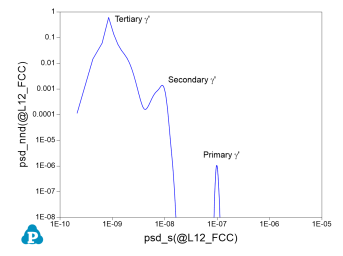

Figure 1 and Figure 2 show the evolution of the average size and volume fraction of the grain and precipitate phase. As can be seen, during the isothermal annealing at 800 °C, the precipitate phase nucleates. Both grain and precipitate phase start to grow. At the end of the isothermal annealing, there is around 10% γ’ phase and the average grain size grows from 1 μm to around 1.5 μm. In the following continuous cooling stage, secondary and tertiary γ’ form as indicated in Figure 3. Accordingly, the average particle size decreases due to the precipitation of these small particles (Figure 1 in red color). The grain growth rate slows down at low temperatures (Figure 1 in blue color).